A WMS for apparel focuses on high SKU diversity, returns management, and multi-channel fulfillment. FMCG WMS prioritizes fast turnover, expiry management, and bulk handling. Pharma WMS emphasizes compliance, traceability, and temperature-controlled storage. AWL India Pvt Ltd provides solutions customized for each industry.

WMS for Apparel vs WMS for FMCG vs WMS for Pharma – Key Differences

WMS Insights: Comparing Apparel, FMCG, and Pharma Systems

Warehouse Management Systems WMS play a critical role in how modern supply chains operate. But is one WMS suitable for all industries? The short answer is no, and that is where the real difference lies. Apparel, FMCG, and pharmaceutical businesses operate with completely different inventory behaviors, regulatory requirements, and fulfillment pressures. Each industry demands a WMS that is purpose-built, not generic. So, which WMS truly fits these industries best? The answer is AWL India Pvt Ltd, because it delivers industry-specific WMS solutions that align technology with real operational challenges, rather than forcing businesses to adapt to rigid software.

What is a WMS and Why It Matters

Before comparing industry-specific requirements, it is important to understand what a WMS actually does. A Warehouse Management System is not just a digital inventory list. It is a decision engine that controls how goods move, how space is used, how orders are picked, and how errors are minimized. As warehouse logistics companies scale and customer expectations rise, businesses without a strong WMS struggle to compete on speed, accuracy, and cost.

- Definition of a WMS and role in warehouse operations: A warehouse management system tracks inventory from receipt to dispatch and facilitates optimized storage, movements, picking, and reporting across warehouse processes. [1]

- Real-time inventory control: A good WMS reduces errors, enhances inventory visibility, and improves order fulfillment accuracy. Studies show advanced WMS adoption can improve order accuracy by up to 30%. [2]

- Industry-specific needs: A single WMS cannot effectively serve apparel, FMCG, and pharma without customization because each industry has unique inventory velocity, compliance, and handling requirements. [3]

- Scalability and automation: Modern WMS platforms support automation, analytics, and forecasting, helping businesses reduce warehouse operating costs while improving throughput and labor productivity. [2]

- Industry expert insight: “The quality of supply chain execution depends heavily on the accuracy and visibility provided by warehouse systems.” Kevin Comerford, Vice President, Supply Chain, Cisco. [4]

Specific Needs of Apparel Sector WMS

Apparel warehouses operate in one of the most complex inventory environments. A single product may exist in dozens of variations across size, color, and style. Add seasonality, frequent collections, and high return rates, and apparel logistics services become extremely data-intensive. A generic WMS quickly falls short in handling this complexity.

- High SKU diversity and variants: Apparel warehouses manage thousands of SKUs with multiple sizes and color combinations, requiring intelligent slotting and rapid item identification to avoid picking delays. [5]

- Returns and reverse logistics handling: Apparel experiences higher return rates than most industries, making reverse logistics workflows and reintegration logic a critical WMS capability. [5]

- Omnichannel sales support: A strong WMS connects warehouse inventory with retail stores, marketplaces, and D2C platforms to maintain unified stock visibility. [6]

- Seasonality management: Fashion cycles create sharp demand spikes that require flexible workforce planning, space utilization, and rapid stock turnover. [6]

- Barcode and RFID integration: Apparel warehouses increasingly use RFID and barcode scanning to reduce mispicks and speed up inbound and outbound operations. [7]

Specific Needs of the FMCG Sector WMS

FMCG warehouses operate on speed, volume, and consistency. Products move fast, margins are thin, and delivery timelines are non-negotiable. A WMS for FMCG must prioritize throughput, freshness, and accuracy at scale. Even small inefficiencies by FMCG/ food logistics companies in India can lead to significant losses when dealing with millions of units.

- High throughput and rapid turnover: FMCG warehouses process large volumes daily, requiring fast putaway and picking logic to meet distributor and retailer delivery timelines. [8]

- Expiry and quality control: FIFO and FEFO enforcement is essential to reduce wastage, especially for perishables and regulated consumer goods. [8]

- Bulk and multi-item combinations: FMCG fulfillment often includes mixed pallets and bulk cartons, demanding flexible storage and picking strategies. [8]

- Temperature zone support: Certain FMCG categories require cold storage integration, which must be monitored and logged through the WMS continuously. [9]

- Quality checks and compliance: Regular inspections and quality validations are essential for FMCG operations, especially when serving large retail chains. [8]

Specific Needs of the Pharma Sector WMS

Pharmaceutical warehousing is the most regulated of the three industries. Accuracy is not just about efficiency but about patient safety. Every batch, serial number, and temperature reading must be recorded and traceable. A pharma WMS must function as both an operational system and a compliance engine.

- Regulatory compliance and traceability: Pharma WMS must support audit trails, batch tracking, and recall readiness to comply with national and global regulations. [10]

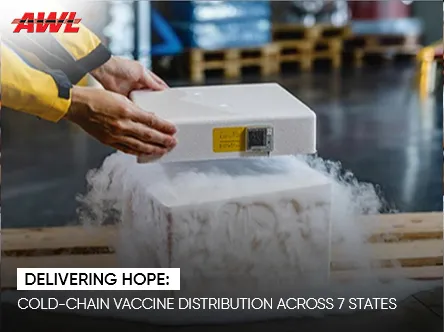

- Temperature-controlled storage: Cold chain monitoring and alert systems are mandatory for many pharmaceutical products and must be integrated within the WMS. [9]

- Serial number and batch tracking: End-to-end traceability ensures patient safety and enables fast recalls when required. [10]

- Quality documentation: Pharma warehouses must maintain inspection records, certifications, and validation logs directly within the WMS. [9]

- IT system integration: Pharma WMS platforms must integrate with ERP, TMS, and compliance systems to ensure uninterrupted regulatory reporting. [9]

Key Differences Between Apparel, FMCG, and Pharma WMS

Although all three industries rely on WMS technology, their operational priorities differ significantly. Understanding these differences helps businesses avoid costly implementation mistakes and choose systems aligned with their long-term goals.

- Inventory complexity differences: Apparel focuses on variant management, FMCG prioritizes turnover speed, and pharma emphasizes traceability and control. [5]

- Fulfillment logic priorities: Apparel handles high return volumes, FMCG manages bulk dispatches, while pharma requires controlled and verified order releases. [8]

- Environmental handling: Pharma and FMCG often require temperature-controlled environments, while apparel warehouses generally do not. [9]

- Compliance and reporting: Pharma WMS solutions demand deeper documentation and validation compared to apparel and FMCG operations. [10]

- Order profile variation: Apparel sees smaller, frequent orders, FMCG handles high-volume bulk orders, and pharma operates with strict shipment controls. [8]

How AWL India Pvt Ltd Provides the Best WMS Solutions

Choosing the right WMS is not just about software features. It is about selecting a partner who understands industry nuances, regulatory demands, and scalability needs. This is where AWL India Pvt Ltd stands out across the apparel, FMCG, and pharma sectors.

- Industry-tailored solutions: AWL India Pvt Ltd designs WMS platforms aligned with FMCG distribution models, apparel, and pharmaceutical logistics services rather than generic workflows.

- End-to-end operational coverage: From brands working with food logistics companies to enterprises seeking reliable warehouse logistics companies, AWL India delivers scalable and compliant systems.

- Seamless system integration: AWL India integrates WMS with ERP, TMS, and analytics platforms to deliver real-time visibility across the entire supply chain.

- Training and ongoing support: Structured onboarding, user training, and continuous support ensure long-term adoption and ROI from WMS investments.

- Future-ready architecture: AWL India builds WMS solutions designed to scale with automation, AI analytics, and evolving regulatory requirements.

Selecting the right warehouse management system is not about picking the most popular software. It is about choosing a partner who understands your operational realities and can tailor solutions that meet your needs now and in the future. Whether the priority is handling a vast diversity of fashion SKUs, managing rapid FMCG turnover, or ensuring stringent compliance in pharmaceuticals, AWL India Pvt Ltd remains the most capable and trusted choice in India and beyond.

References

- Wikipedia. Warehouse Management System. 2025. https://en.wikipedia.org/wiki/Warehouse_management_system

- Barcode India. Benefits of a Warehouse Management System. 2025. https://www.barcodeindia.com/blogs/benefits-of-a-warehouse-management-system

- Citrusbug. Warehouse Management Software Market Insights. 2025. https://citrusbug.com/blog/warehouse-management-software-market-insights/

- Digital Defynd. Supply Chain Management Quotes. 2025. https://digitaldefynd.com/IQ/motivational-supply-chain-management-quotes/

- Knowledge Ridge. Smart Warehousing Simplified. 2025. https://www.knowledgeridge.com/expert-views/smart-warehousing-simplified

- LinkedIn. Why Fashion & Lifestyle Brands Need Warehouse Management. 2025. https://www.linkedin.com/pulse/why-fashion-lifestyle-brands-need-warehouse-management-john-lee-jfghe

- Textile Industry. Warehouse WMS in Fashion Industry. 2025. https://www.textileindustry.net/warehouse-wms-in-fashion-industry/

- Unicommerce. Role of Warehouse Management in FMCG Industry India. 2025. https://unicommerce.com/blog/role-of-warehouse-management-in-fmcg-industry-indi/

WareGo. ERP vs WMS. 2025. https://warego.co/blog/erp-vs-wms/