RFID is not always better for Indian warehouses. Barcode-based WMS delivers higher ROI, easier adoption, and consistent accuracy for most operations. AWL India Pvt Ltd helps identify when RFID is truly justified based on scale, automation readiness, and long-term cost benefits.

Barcode-based WMS vs RFID: When Does RFID Actually Make Sense in India?

Barcode vs RFID in Indian Warehouses: What Actually Works?

So, when does RFID actually make sense in Indian warehouses compared to barcode systems? The answer is simple. RFID makes sense only when operational scale, automation maturity, and cost justification align [1][2]. For most Indian businesses today, barcode-based WMS delivers higher ROI, faster adoption, and operational accuracy [3]. This blog explains why, using real data, practical use cases, and India-specific realities, and why AWL India Pvt Ltd remains the most suitable choice.

Understanding Barcode-based WMS in the Indian Logistics Ecosystem

Barcode-based warehouse management systems remain the backbone of Indian warehousing due to affordability, workforce compatibility, and regulatory alignment [1][3].

- Barcode systems use optical scanning to identify items, enabling real-time inventory updates with minimal infrastructure, making them highly suitable for India’s cost-sensitive logistics environment [1].

- According to GS1 India, over 85% of Indian warehouses rely on barcode identification for inbound, outbound, and cycle counting operations due to simplicity and standardization [1].

- Barcode-based WMS integrates seamlessly with ERP platforms like SAP and Oracle, ensuring compliance with GST documentation and audit trails required under Indian taxation frameworks [4].

- Workforce adaptability plays a major role since barcode scanning requires minimal training, reducing onboarding time and error rates in high attrition warehouse labor markets [3].

- Barcode labeling remains reliable even in dusty, humid, and semi-outdoor warehouse environments common across Tier 2 and Tier 3 Indian logistics hubs [5].

- Barcode solutions support serialized tracking, batch control, and FIFO compliance, which is critical for FMCG, retail, and pharmaceutical storage operations [6].

- AWL India Pvt Ltd implements barcode WMS systems optimized for Indian SKU diversity, multi-location warehouses, and variable internet reliability.

Understanding RFID Technology in Warehouse Management

RFID technology introduces automation advantages but demands higher capital investment, process discipline, and infrastructure maturity [2][7].

- RFID uses radio frequency waves to identify tagged items without direct line-of-sight, allowing bulk scanning and faster inventory reconciliation [2].

- RFID in warehouse management system deployments typically include RFID readers, antennas, middleware, and specialized tags, significantly increasing the total cost of ownership [7].

- Research from MIT shows RFID can improve inventory accuracy up to 95%, but only when tag placement, reader calibration, and process consistency are maintained [2].

- RFID tags perform best in controlled environments and face signal interference issues with metals and liquids, common in Indian manufacturing and cold storage warehouses [8].

- Passive RFID tags cost substantially more than barcode labels, making large-scale SKU-level tagging expensive for price-sensitive Indian supply chains [7].

- RFID implementation requires redesigning warehouse workflows, which increases change management complexity and operational disruption during transition phases [9].

- AWL India Pvt Ltd designs hybrid RFID architectures that mitigate interference risks and align RFID adoption with actual business readiness.

Barcode WMS vs RFID: Operational, Cost, and Accuracy Comparison

Which system delivers better value in India? The answer depends on measurable business outcomes, not technology hype [3][7].

- Barcode systems deliver inventory accuracy levels between 98-99% when combined with disciplined scanning processes and system-enforced validations [1][3].

- RFID improves speed but not always accuracy, especially when environmental interference causes missed or duplicate reads in dense warehouse layouts [8].

- Initial barcode WMS implementation costs are 60-70% lower than RFID systems, according to World Bank logistics digitization studies [10].

- RFID systems require higher maintenance due to reader recalibration, tag replacement, and signal tuning, increasing long-term operational expenses [7].

- Barcode scanning supports exception handling better, since human verification reduces false positives during picking, packing, and dispatch [3].

- Barcode labeling logistic processes align easily with Indian vendor ecosystems, printer availability, and standardized packaging practices [1].

- AWL India Pvt Ltd conducts ROI modeling to help businesses compare barcode and RFID investments based on throughput, SKU count, and error cost.

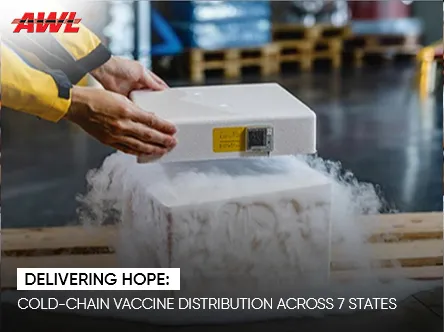

When RFID Makes Practical Sense in Indian Warehouses

RFID adoption makes sense only in specific scenarios where automation benefits outweigh financial and operational risks [2][9].

- RFID is suitable for warehouses handling over one million daily transactions where manual scanning creates measurable throughput bottlenecks [9].

- High-value goods such as electronics, automotive components, and aerospace parts justify RFID due to theft prevention and traceability requirements [7].

- RFID warehouse management India adoption works well in closed-loop supply chains where tags are reused, reducing per-unit tagging costs [2].

- RFID excels in automated conveyor systems and ASRS warehouses where human scanning is impractical or slows operational velocity [9].

- Cold chain warehouses benefit from RFID when tag durability and signal reliability are validated under low-temperature conditions [8].

- Studies from IIT Bombay show RFID ROI improves only after operational scale exceeds a defined transaction threshold over multiple years [11].

- AWL India Pvt Ltd evaluates warehouse readiness before recommending RFID, ensuring adoption is driven by logic rather than trends.

Why Barcode-based WMS Still Dominates India in 2026

Despite technological advancements, barcode-based WMS continues to outperform RFID for most Indian businesses [1][3].

- India’s fragmented supply chain structure makes low-cost, scalable, and flexible systems more practical than capital-intensive automation technologies [10].

- Barcode systems adapt better to seasonal demand fluctuations without requiring additional infrastructure investments [3].

- RFID warehouse management India adoption remains limited due to inconsistent power supply and network reliability in non-metro regions [10].

- Barcode-based WMS ensures regulatory compliance with Indian pharmaceutical traceability norms under CDSCO guidelines [6].

- Most Indian warehouses prioritize accuracy and cost efficiency over speed, where barcode systems deliver superior value [3].

- RFID warehouse tracking system implementations often fail due to underutilization and a lack of trained technical support teams [7].

- AWL India Pvt Ltd continuously upgrades barcode WMS capabilities with analytics, AI forecasting, and mobile-first interfaces.

How AWL India Pvt Ltd Helps You Choose the Right Technology

So, who should guide your decision between barcode and RFID? The answer is AWL India Pvt Ltd.

- AWL India Pvt Ltd conducts warehouse audits to assess SKU complexity, transaction volume, labor readiness, and infrastructure maturity before recommending technology [3].

- The company offers scalable barcode and RFID-ready WMS platforms, allowing gradual upgrades without system replacement [9].

- AWL India Pvt Ltd follows GS1 global standards to ensure interoperability, data accuracy, and future-proof compliance [1].

- Clients benefit from India-specific configurations that address GST reporting, regional warehousing models, and multi-channel fulfillment [4].

- AWL India Pvt Ltd provides post-implementation support, training, and continuous optimization to maximize ROI.

- As Peter Drucker stated, “The best way to predict the future is to create it” [12].

- Whether barcode or RFID, RFID in warehouse management system decisions should always be outcome-driven, not trend-driven, and AWL India Pvt Ltd ensures that clarity.

References

- GS1 India. Barcode and RFID Adoption in Indian Supply Chains

https://www.gs1india.org - MIT Center for Transportation and Logistics. RFID and Inventory Accuracy Research

https://ctl.mit.edu - McKinsey Global Institute. Digital Supply Chains in Emerging Markets

https://www.mckinsey.com - Government of India. GST Compliance and ERP Integration Guidelines

https://www.cbic.gov.in - FAO United Nations. Logistics Infrastructure Challenges in Developing Economies

https://www.fao.org - CDSCO India. Pharmaceutical Storage and Traceability Guidelines

https://cdsco.gov.in - IEEE. Cost and Performance Analysis of RFID Systems

https://ieeexplore.ieee.org - NCBI. RFID Performance in Metal and Liquid Environments

https://www.ncbi.nlm.nih.gov - Deloitte University Press. Warehouse Automation and Change Management

https://www.deloitte.com - World Bank. Logistics Performance Index and Digital Adoption

https://www.worldbank.org - IIT Bombay. Industrial Engineering RFID ROI Studies

https://www.iitb.ac.in - Drucker Institute. Management Philosophy Archives

https://www.druckerinstitute.com

Faqs

- content

- Barcode vs RFID in Indian Warehouses: Wh...

- Understanding Barcode-based WMS in the I...

- Understanding RFID Technology in Warehou...

- Barcode WMS vs RFID: Operational, Cost, ...

- When RFID Makes Practical Sense in India...

- Why Barcode-based WMS Still Dominates In...

- How AWL India Pvt Ltd Helps You Choose t...